Square Enameled Aluminum Wire

Introduction

Square enameled aluminum wire is a specialized type of wire used in various electrical and electronic applications. It combines the benefits of aluminum’s lightweight and cost-effectiveness with the advantages of a square cross-sectional shape and an insulating enamel coating. It is made of oxygen free rod or electrical aluminum rod by a certain size of the die drawing or extrusion of the wire, the insulation paint through many times of the winding wire.

Enameled Square Aluminum Wire technical parameters

| Name | Square Enameled Aluminum Wire |

| Conductor | Aluminum |

| Dimension | Thickness(a)/Width(b):1.2-8mm |

| Thermal Class | 120(Class E), 180(Class H), 200(Class C), 220(Class C+), 240(Class HC) |

| Insulation Thickness: | G1, G2 or single build, heavy build |

| Standard | IEC 60317-16,60317-16/28,MW36 60317-29 BS6811, MW18 60317-18 ,MW20 60317-47 |

| Certificate | UL |

| Packing | 30kg-150kg ply-wood spool(250*400 / 250*500/ 250*600/ 250*730) |

Insulation build, thermal calss & material

| Insulation Build | Insulation Type | Special Thermal Class |

| Single Heavy Triple Quadruple Special |

Polyurethane – 155 / 180 Poly-Nylon – 155 / 180 Polyester – 180 Polyester – 200 Polyurethane Bondable Solderable Polyester – 180 Formvar ML Special |

For Poly and Poly-Nylon insulations specify 155 or 180 thermal class |

Why choose the enameled square aluminum wire for small machine?

Space Efficiency

High Packing Density: Square wire allows for a more compact winding configuration compared to round wire. This higher packing density means that more wire can fit into the same space, which is particularly beneficial in small machines where space is at a premium.

Optimized Design: The ability to pack wires more efficiently can lead to more optimized and compact machine designs, which is essential in applications where minimizing the size and weight of the machine is critical.

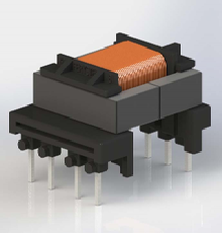

- Inductors

- small motors

- ballast